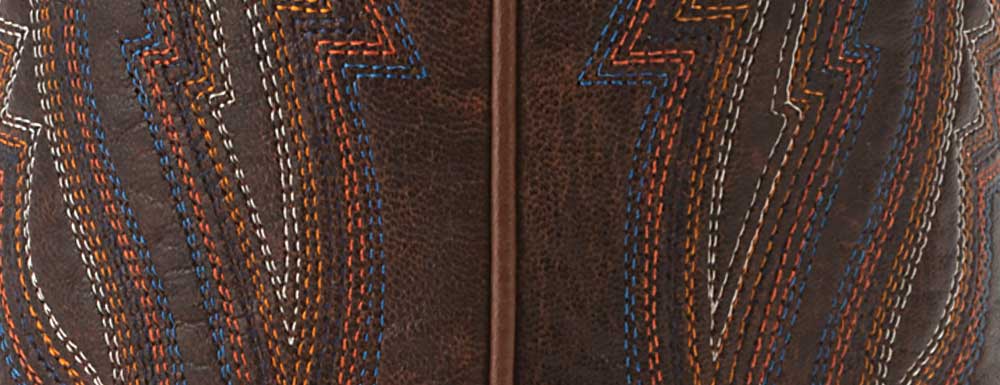

Custom wheel leather welts and rands just like they did in the good ol’ days. R. Watson western boots have 8 stitches per inch, eliminating the softball stitch look of some other brands. We offer a classic finish like the boots your Grandpa handed down to you that also stood the test of time.

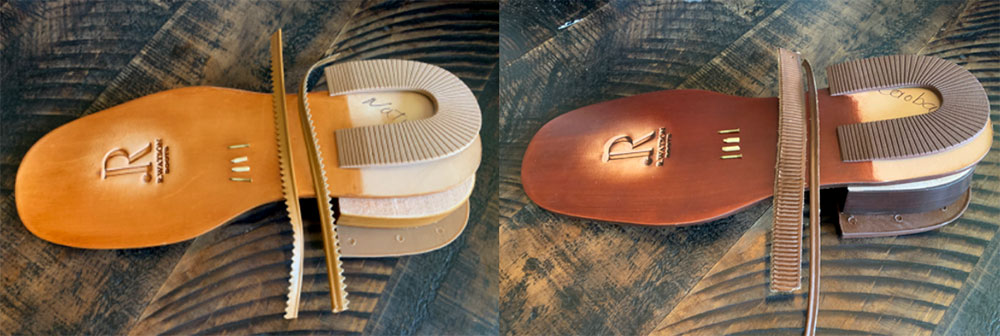

To provide the most stability and durability possible, we developed a solid steel shank system that you’ll find in an R. Watson Boot. The solid steel shank system is then incorporated into a 1 piece insole system so you will never get that dreaded squeak again. This is something your friends and family will thank us for later.

From toe to heel, we’ve got you covered. Each boot has a comfort system which consists of layered padding from front to back with a leather top lining that allows for maximum comfort. No more heal covers peeling back when you take you foot out of the boot. It all adds up to a boot you can wear all day without batting an eye, and our customers are raving about it.